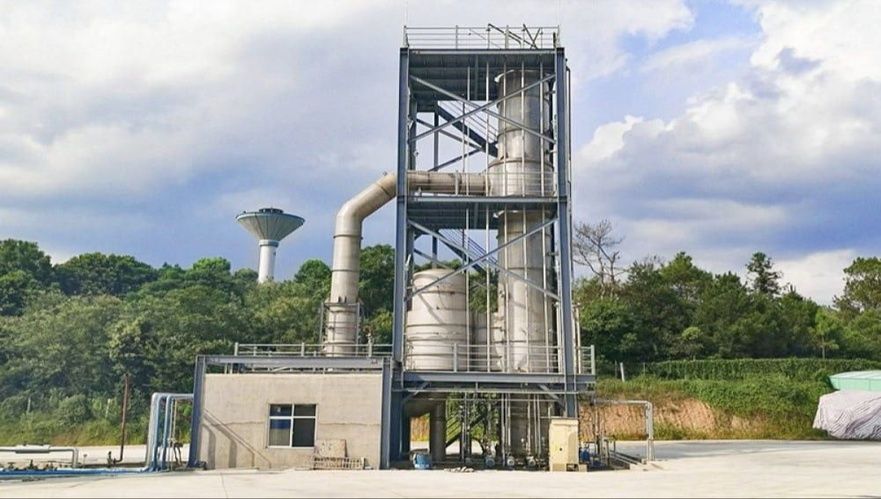

MEE (Multi Effect Evaporator) and MVR (Mechanical Vapor Recompression)

Advanced Effluent Volume Reduction with Thermal Efficiency

Multi Effect Evaporators are engineered systems used for minimizing liquid effluent volumes through controlled evaporation. BT Water’s MEE systems are custom-designed for high-TDS, high-COD wastewater generated by industries such as pharma, textile, chemical, and distilleries — where zero liquid discharge (ZLD) is mandated.

By using multiple stages (effects), each operating at progressively lower pressures, MEEs maximize heat efficiency and reduce steam consumption — ensuring cost-effective performance with environmental compliance.

How It Works

The process involves heating wastewater to its boiling point in a series of evaporator bodies. Vapors generated from one stage are used as the heating medium for the next, reducing energy demand per unit of water evaporated. The final condensate is often reusable, while the concentrated slurry is directed to further drying or disposal.

System Configuration

| Component | Description |

|---|---|

| Evaporator Effects | Falling Film / Forced Circulation / Rising Film, depending on feed characteristics |

| Preheater | Increases feed temp using condensate or bleed vapor |

| Thermo-Vapor Compressor (Optional) | Boosts energy reuse between effects |

| Heat Exchangers | Shell & Tube or Plate-type, SS316/SS316L construction |

| Crystallizer / ATFD (Optional) | For final solid separation in ZLD |

| Vacuum System | Steam ejector or water ring vacuum pump |

| Control System | PLC/SCADA based for temperature, pressure, and flow control |

Performance Metrics

- Evaporation Capacity: 500 LPH to 100,000+ LPH

- Steam Economy: 1.8 to 2.5 (higher with MVR integration)

- Operating Pressure: 0.1 to 1.2 bar (vacuum stages)

- Material of Construction: SS316/SS316L/Ti/Alloy 2205 depending on feed

Application Industries

- Pharmaceuticals

- Dye & Intermediates

- Agrochemicals

- Distilleries

- Dairy & Food Processing

- Pulp & Paper

- ETP/RO reject handling in ZLD plants

Key Benefits

- Significant effluent volume reduction

- High thermal efficiency and low operational cost

- Reusable condensate recovery

- Rugged construction for corrosive fluids

- Fully automated or semi-auto options

- Tailored for Zero Liquid Discharge (ZLD) goals

Why Choose BT Water

With decades of experience and in-house thermal design expertise, BT Water provides engineered evaporator systems tailored to your wastewater matrix. From pilot testing to commissioning and lifecycle support — our focus is reliability, efficiency, and long-term cost savings.

Optional Add-Ons

- Crystallizer or ATFD Integration

- CIP (Clean-in-Place) System

- Online monitoring & data logging

- Hybrid Solar Heating Support (on request)

Mechanical Vapour Recompression (MVR)

Ultra-Efficient Zero Discharge with Minimal Steam Dependency

Overview

Mechanical Vapour Recompression (MVR) is an energy-efficient evaporation technology that recycles its own vapor by compressing and reusing it as a heat source. MVR systems drastically reduce steam and fuel consumption, offering an eco-friendly and economically sustainable alternative to traditional thermal evaporation.

Ideal for industries with continuous wastewater loads and high energy bills, BT Water’s MVR systems are precision-engineered for long operating cycles with minimal maintenance.

Working Principle

The vapor from the evaporator is compressed using a mechanical compressor, which increases its pressure and temperature. This high-energy vapor is then reused to heat the feed, eliminating the need for external steam after start-up.

System Components

| Component | Description |

|---|---|

| Evaporator Body | Falling Film / Forced Circulation design |

| MVR Compressor | Centrifugal / Roots / Screw-type, energy-optimized |

| Pre-heaters | Energy recovery from condensate |

| Condensers | Efficient vapor-liquid separation |

| Control Panel | Advanced PLC/SCADA control with VFDs for variable load handling |

| Material | SS316L, Duplex, or Titanium, depending on effluent nature |

Performance Metrics

- Steam Consumption: Near-zero after start-up

- Power Consumption: ~20–40 kWh/m³ (application-dependent)

- Evaporation Rate: 1000–80,000 LPH

- Payback Period: Typically <=2 years due to energy savings

Advantages

- Extremely low operating cost compared to MEE

- Fast return on investment for high-load effluent plants

- Compact footprint, lower utility demand

- Sustainable and ideal for green manufacturing certifications

- Low noise, low vibration operation

Where MVR Fits Best

- Continuous process plants with high effluent volume

- Pharma, biotech, and chemical process industries

- Distilleries & fermentation industries

- Where energy cost is a limiting factor for ZLD

BT Water Edge

Our MVR systems are not off-the-shelf — we conduct effluent testing, thermal modeling, and ROI analysis before commissioning. With international-grade compressors and high-reliability instrumentation, we ensure maximum uptime and lowest lifecycle cost.

Need Technical Consultation?

Our thermal experts can evaluate your effluent parameters and recommend the ideal evaporation strategy — standalone MEE, hybrid MEE+MVR, or full MVR system.