Electrodeionization (EDI) System

High-Purity Water Without Chemicals

Electrodeionization (EDI) is a chemical-free water polishing process used after reverse osmosis (RO) to produce consistent, high-purity water. It combines ion exchange resins and electricity to continuously remove remaining dissolved ions, without the need for chemical regeneration.

At BT Water Treatment Pvt. Ltd., we supply integrated EDI systems engineered for applications that demand ultrapure water—such as pharmaceuticals, electronics, and power generation.

How EDI Works

EDI uses mixed-bed ion exchange resins placed between cation and anion exchange membranes. As feedwater passes through the resin, remaining ions (after RO) are captured. A low-voltage DC current is applied, which continuously regenerates the resins and drives the ions through the membranes into a concentrate stream, keeping the resins active without interruption.

Technical Parameters

| Parameter | Specification |

|---|---|

| Inlet Water | RO Permeate (TDS < 30 ppm) |

| Output Water Quality | 16–18 MΩ·cm resistivity |

| Flow Range | 250 LPH to 10,000+ LPH (modular) |

| Silica Removal | < 0.1 ppm |

| Power Requirement | Typically < 100 W per module |

| Recovery Rate | Up to 95% |

| Operating Pressure | 2 – 6 bar |

| Configuration | Skid-mounted, modular frame |

| Membrane/Module Brands | Ionpure / Dow / Evoqua / Equivalent |

Key Features

- Continuous Operation: No downtime for regeneration

- No Chemical Handling: Eliminates acid/caustic usage

- Compact Footprint: Modular design for easy expansion

- Consistent Output: Reliable quality for critical processes

- Low Maintenance: Fewer moving parts, minimal manual intervention

Applications

- Pharmaceuticals: USP-grade purified water, WFI pre-treatment

- Electronics: Semiconductor washing, microchip production

- Power Plants: High-pressure boiler feedwater

- Laboratories: Analytical and instrumentation water

- Food & Beverage: Product contact and final rinse

System Integration

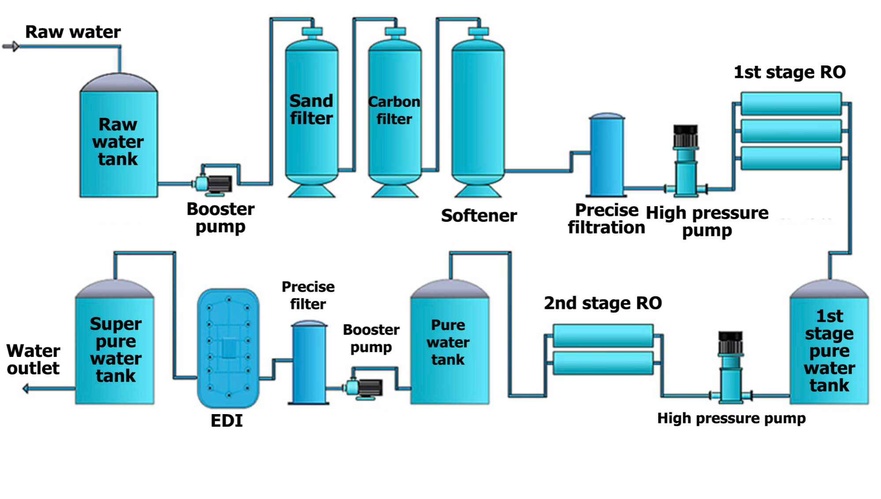

EDI systems are always used after RO systems to polish the water. A typical configuration: Raw Water → Pre-treatment → RO → EDI → Storage & Distribution

We offer both standalone EDI skids and complete RO + EDI systems tailored to your industry requirements.

Why Choose BT Water

- Decades of experience in high-purity water systems

- Pre-engineered and custom-built solutions

- Support for validation documentation (GMP/USFDA/ISO)

- After-sales service, module replacements, and AMC support