Effluent Treatment Plant (ETP)

Effluent water treatment plant (ETPs) is a vital infrastructure for industries to treat their wastewater before releasing it back into the environment. With water scarcity intensifying globally, ETP Plant allows companies to reuse and recycle water, reducing their environmental footprint. As a leading Effluent Treatment Plant Manufacturer, we understand the importance of reliable and efficient systems tailored to industrial needs. This article will provide a comprehensive overview of ETP Plants - their purpose, processes, benefits, and design considerations. Partnering with a trusted ETP Manufacturer ensures sustainable compliance and optimized performance.

What is an Effluent Water Treatment Plant and Why is it Important?

An effluent water treatment plant is designed specifically to treat industrial wastewater and effluents using various physical, chemical and biological treatment methods. The objective is to remove pollutants from the wastewater so it can be safely discharged into the environment or reused/recycled.

-

Having an ETP Plant is critical for industries because:

- It enables water conservation by allowing treated effluent to be reused or recycled. This reduces freshwater intake.

- It removes toxic pollutants from wastewater before discharging it thereby preventing environmental damage.

- It helps companies comply with wastewater discharge norms set by governmental pollution control boards. Non-compliance can attract heavy penalties.

- Reusing treated effluent reduces costs for water acquisition.

Thus, ETP Plants allow industries to mitigate their environmental impact and use water sustainably, which is the need of the hour.

What Are the Different Industrial Effluents?

-

Industrial effluents can contain various contaminants depending on the industry such as:

- Oils and Grease: Food processing units, oil refineries, automotive industry

- Toxic Materials: Pesticides industry, metal processing industry, tanneries

- Organic Pollutants: Distilleries, dairy industry, beverage industry Inorganic

- Contaminants: Textiles industry, paper mills, dye industry

Since the composition of contaminants varies significantly based on the industry, ETPs use different configurations of treatment methods to specifically remove the effluent’s pollutants.

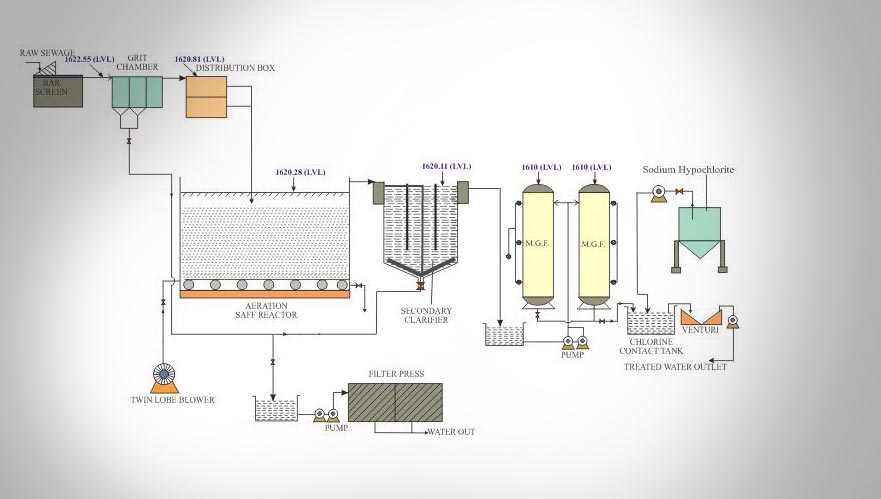

Overview of the Effluent Treatment Process

Industrial wastewater treatment is multi-stage process, deployed sequentially to remove different kinds of contaminants:

Preliminary Treatment

First stage where large floating solids like wood and plastic are removed using screens and grit chambers to avoid damaging subsequent equipment.

Primary Treatment

Involves settling tanks to allow suspended inorganic solids to sink to the bottom, which are removed. Chemical coagulants can also be added to clump small suspended particles together aiding removal. This helps remove much of the suspended solids and trace organics.

Secondary Treatment

Here biological processes are used to further reduce organics and suspended solids by using microbes that break down and feed on the organics. Methods like activated sludge process, trickling filters and aeration tanks are common.

Tertiary Treatment

Final polishing stage with advanced processes like filtration using sand/activated carbon to remove

trace impurities. Chlorine/UV can also be used to disinfect water before reuse or discharge.

Technologies like reverse osmosis allow high water recovery.

The specific treatment methods used

can vary based on effluent characteristics. Multiple stages help systematically remove contaminants

to achieve the desired discharge quality.

Benefits of Installing an Effluent Water Treatment Plant

1. Enables Water Conservation: Treated effluent can be recycled/reused rather than extracting freshwater. This allows industries to reduce water usage substantially.

2. Mitigates Environmental Impact: Removes toxic pollutants from effluent before discharging it thereby preventing pollution of water bodies and land.

3. Compliance with Discharge Norms: Treated effluent meets governmental wastewater discharge guidelines for safe release into the environment.

4. Avoid Penalties: Non-compliance with effluent discharge norms can attract heavy fines, litigations or even shut down. Having an ETP avoids this.

5. Improves Sustainability Profile: Having an ETP plant and reuse program demonstrates environmental responsibility to stakeholders. This boosts brand image and public trust.

With the rising adoption of zero liquid discharge mandates, ETP plants are indispensable for industries aiming to minimize their water footprint.

Key Considerations for Designing an ETP

When designing an Effluent Treatment System, some key aspects to evaluate are:

1. Effluent Characterization: The contaminants level and types in the effluent determine treatment methods required. Effluent sampling reveals key design parameters.

2. Desired Water Quality: The intended reuse or discharge location sets standards needed to design the appropriate treatment levels.

3. Effluent Quantity: Current and expected effluent generation rates determine treatment capacity requirements. This may allow modular/phased capacity growth.

4. Land Availability: Sufficient area is required for the ETP’s civil structures, equipment, pumps and piping layout. Limited land may warrant a compact modular ETP with vertical construction.

5. Operating Costs: While lowering initial capex is appealing, it can increase operating costs substantially later. Optimized design cuts life cycle costs.

Key Considerations for Designing an ETP

For ETP plants to continually deliver their expected treatment capabilities, their operation and

maintenance requires dedicated focus. Plants need to be operated round-the-clock by qualified personnel

adhering to detailed standard operating procedures (SOPs).

Staff must monitor all equipment and

processes closely checking parameters like flow rates, pH, dissolved oxygen levels in aeration tanks,

chemical dosing rates etc. Any deviations from optimal ranges must trigger immediate corrective actions

like changing chemical dose or cleaning clogged diffusers. This helps avoid situations impacting

treatment efficacy. Regular sampling with timely lab testing verifies treated water quality. With

disciplined operations as per SOPs, plants achieve consistent peak performance.

Skill Development for Effective Management of Effluent Treatment Infrastructure

Specialized technical skills are imperative for industries to properly operate and manage their effluent water treatment infrastructure. Plant managers and operators must be provided regular training to enhance their competencies in areas such as:

- Water and wastewater treatment principles

- Selection, use and dose optimization of treatment chemicals

- Sampling and lab analysis protocols

- Working of pumps, aerators, filters

- Instrumentation like flow meters

- Troubleshooting procedures

- Regulatory compliance

Upskilling the workforce empowers them to leverage the sophisticated technologies and make appropriate decisions for glitch-free functioning of plants. Industries having a culture of continuous skill development can build top-notch sustainable water management capabilities.

Final Words

With customized design focused on long-term, reliable and efficient operations, ETPs enable industries

to implement sustainable water management. Professional water treatment companies can conduct technical

audits of effluent systems to enhance their performance.

BT Water Treatment specializes in designing

and building customized turnkey effluent water treatment plants. With years of experience handling

complex industrial wastewaters, we can audit your needs, configure optimal treatment systems

incorporating advanced technologies and guide you on efficient operations - enabling compliance and

water recycling. Contact us for a consultation.

Our Methodology

At BT Water Treatment Pvt Ltd, we follow a systematic and scientific methodology for designing and implementing every ETP Plant. Each effluent sample is carefully analyzed to assess its specific parameters, composition, and characteristics. Based on these insights, we conduct treatability studies using various techniques while evaluating the techno-commercial feasibility of each method. This enables us, as a trusted ETP Plant Manufacturer, to design customized Effluent Water Treatment Plants that are tailored to client requirements, ensuring regulatory compliance, operational efficiency, and long-term reliability.

Our Approach

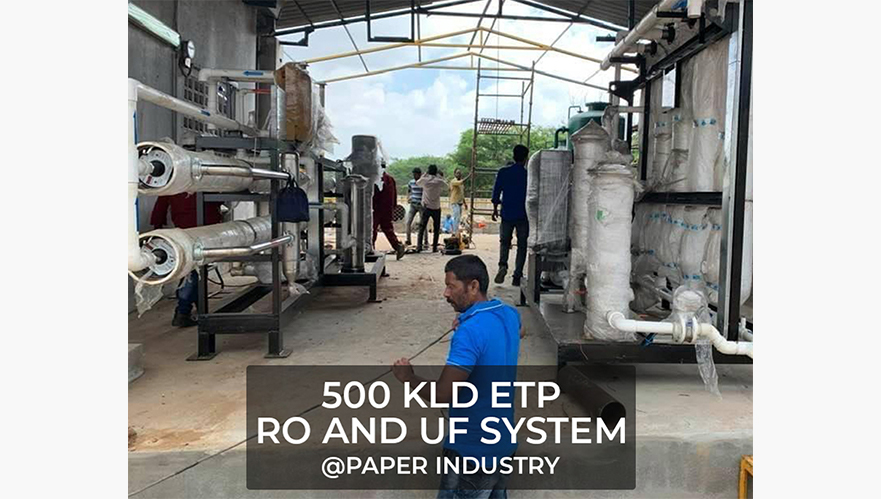

Our approach focuses on sustainability and environmental protection. As leading ETP Plant Manufacturers in India, we design Effluent Water Treatment Plants that are compact, energy-efficient, portable, and robust. By integrating physico-chemical treatment with advanced polishing methods such as sand filtration, activated charcoal adsorption, ozonisation, ultrafiltration (UF), and reverse osmosis (RO), our ETP Plants help clients recover valuable water, minimize waste, and ensure compliance with Pollution Control Board standards—all while reducing operational costs and footprint.

We specialize in effluent treatment by customizing ETP systems based on the specific effluent characteristics of different industries like textiles, chemicals, distilleries, tanneries, and food processing. Our team ensures the treatment process suits your exact operational needs.

Yes, one of the main advantages of installing an ETP Plant is the ability to reuse treated effluent. This significantly reduces freshwater dependency and supports sustainable water management practices.

We are a trusted Supplier of ETP solutions with a proven track record in delivering turnkey Effluent Water Treatment Plants. Our expertise includes system audits, customized design, advanced treatment technologies, and long-term operational support.

We conduct a complete effluent characterization, evaluate land availability, projected water reuse, and environmental regulations. Based on this data, we recommend the most suitable ETP system for your site.

Yes. We not only design and install ETP Plants but also provide operation & maintenance support. We train plant operators, set up SOPs, and help with monitoring and troubleshooting to ensure consistent performance.

Absolutely. We offer technical audits and performance evaluations of existing ETPs and suggest upgrades, retrofitting, or modular expansions to meet current and future regulatory and operational requirements.