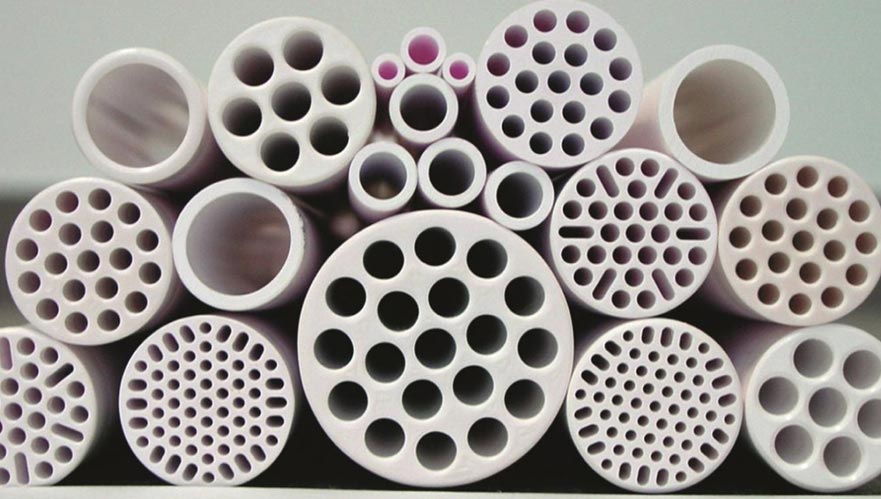

Ceramic membrane is a porous fine ceramic filter which is sintered from Alumina, Titania or Zirconia under ultra high temperature. Ceramic membrane normally has an asymmetrical structure with porous support active membrane layer. The macro porous support ensures the mechanical resistance while the active layer functions separation ranging from Micro filtration, Ultra filtration and even Nano filtration (from 10nm down to 1KD). Ceramic Membrane always runs at a Cross Flow Filtration mode. The turbid fluid goes through membrane layer inside the single channel or a multi channel at a high velocity. Driven by Trans Membrane Pressure (TMP), the clean liquid with micro-molecule pass through the membrane layer vertically to permeation, the solid and big molecule is rejected in retenate. The feed fluid is thus clarified, concentrated and purified.

Our Ceramic membrane filtration systems are come with a host of advantages: they separate mixtures physically. No additives are necessary and the process temperature is not restricted. Filtration with ceramics is a mild, highly selective process without phase transformation. Also, operational costs are limited by closed production cycles and continuous processes.

We manufacture multitubular inorganic ceramic membrane system for a wide range of applications for water filtration, wastewater and industrial processes. We have collaborated with ceramic membranes manufacturers and select the right & suitable membranes for a specific application. The systems are made in house with stringent process and quality conditions. Major advantages of our ceramic membrane systems are

Varieties of Demineralized Water Systems:

- High Abrasion resistance

- Suitable for Operating in high flux rates

- Homogenous pore distribution for better results

- Insensitive to all acids, alkalis & solvents

- High tolerance to chlorine and other oxidation agents.

- High durability

- High temperature application

- Wide operating range in all pH

- Low fouling

- Longer service life

Our ceramic membrane configurations aid in filtering fluids with high concentration of oil, suspended solids and high viscosity. As a result, our membrane systems are suitable for filtration of any kind of water, liquid wastes, leachate, chemical, pharmaceutical, paper mill, petrochemical and agro-food industries effluents; in general, every type of industrial filtration.

APPLICATION AREAS

- Metallurgical industry: Filtration & treatment of Phosphate bath, Degreasing bath, chemical bath, Cutting oils & fluids, Paint effluent, Cleaning water & surface water treatment.

- Pharmaceutical industry: Filtration of formulation process effluent and ingredient effluent, Concentration & recovery of formulates.

- Printing & Paper Industry: Treatment of wash water from printing origin, Flexographic aqueous ink, Black liquor, coating effluent, Paper pulp bleaching effluent and other process effluent

- Textile Industry: Treatment & Recovery of sizing solution, Washing effluents, Ennoblement effluent, dye baths

- Electrical Industry: Treatment of baths and alkaline baths.

- Others: Grey & Black water purification, CIP wastewater treatment, Cosmetic effluent treatment, nuclear waste effluent treatment, Treatment of petroleum waste, Concentration of wastewater & chemicals.